Piercing Operation In Sheet Metal

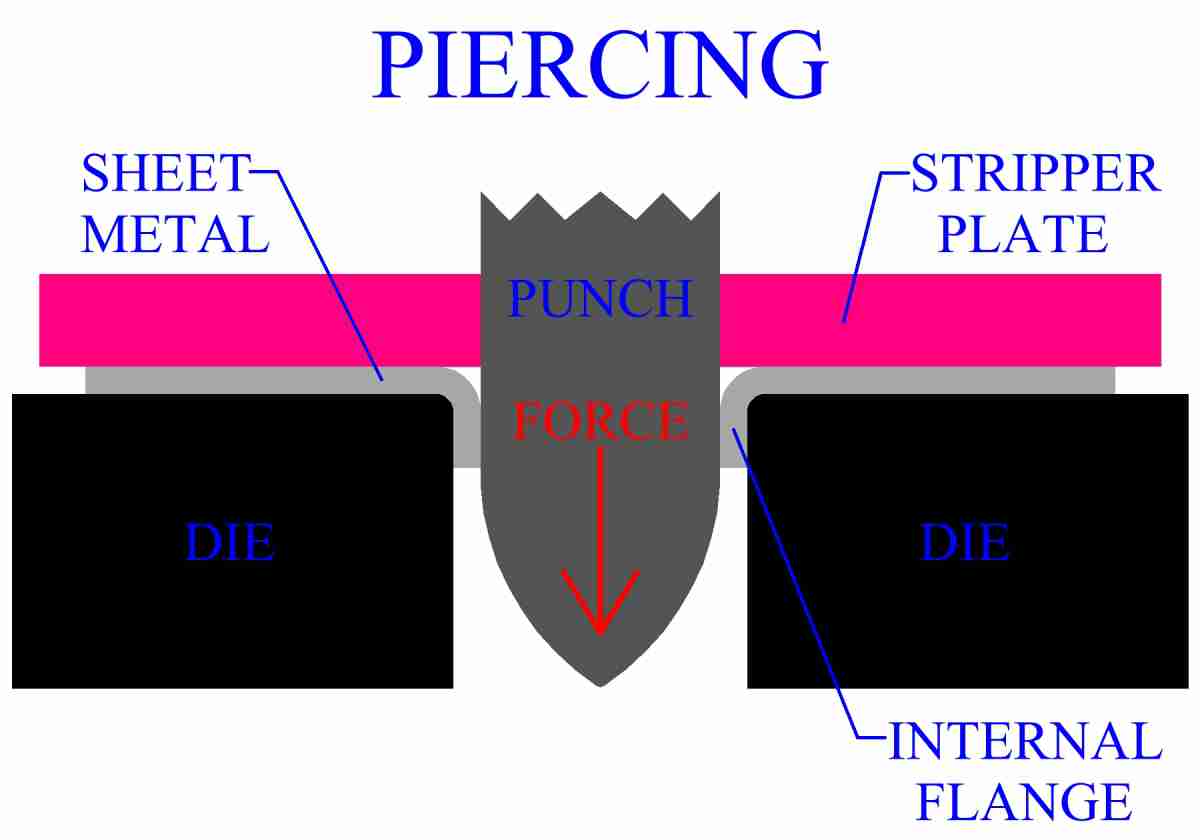

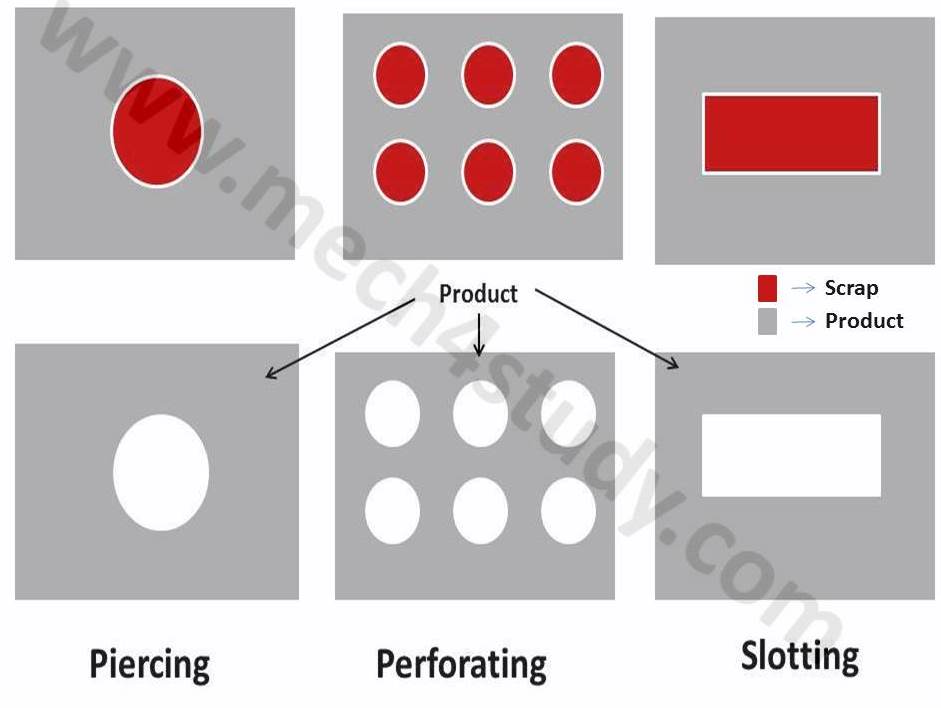

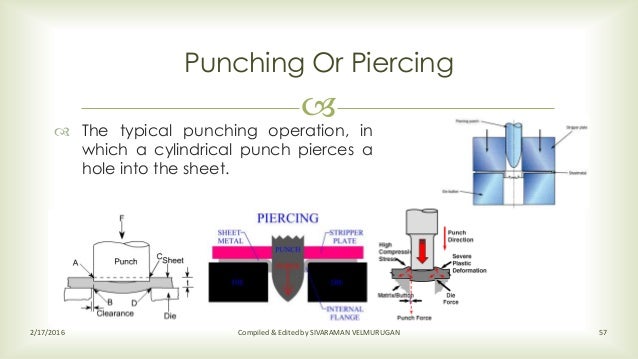

It is a process by which a hole is cut or torn in metal.

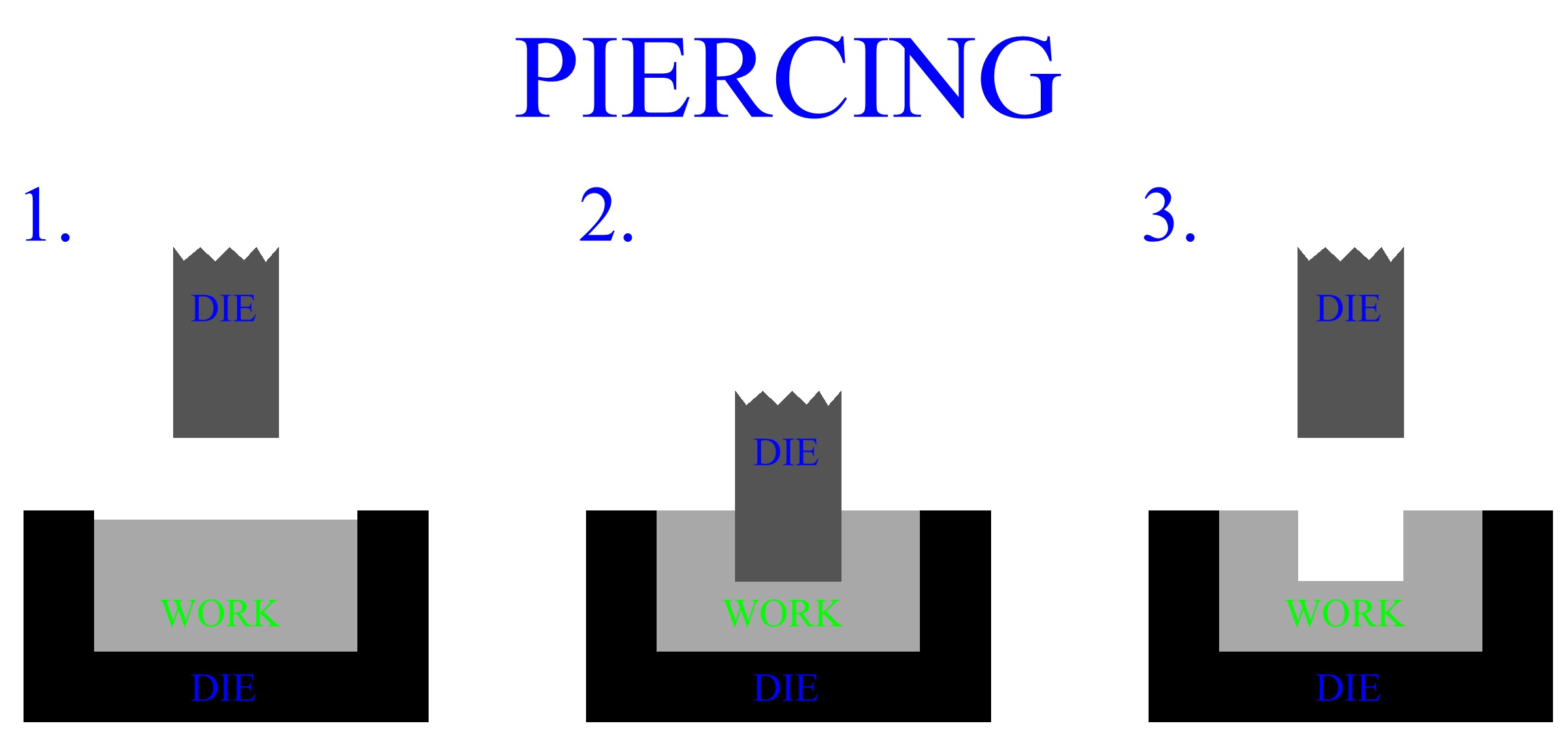

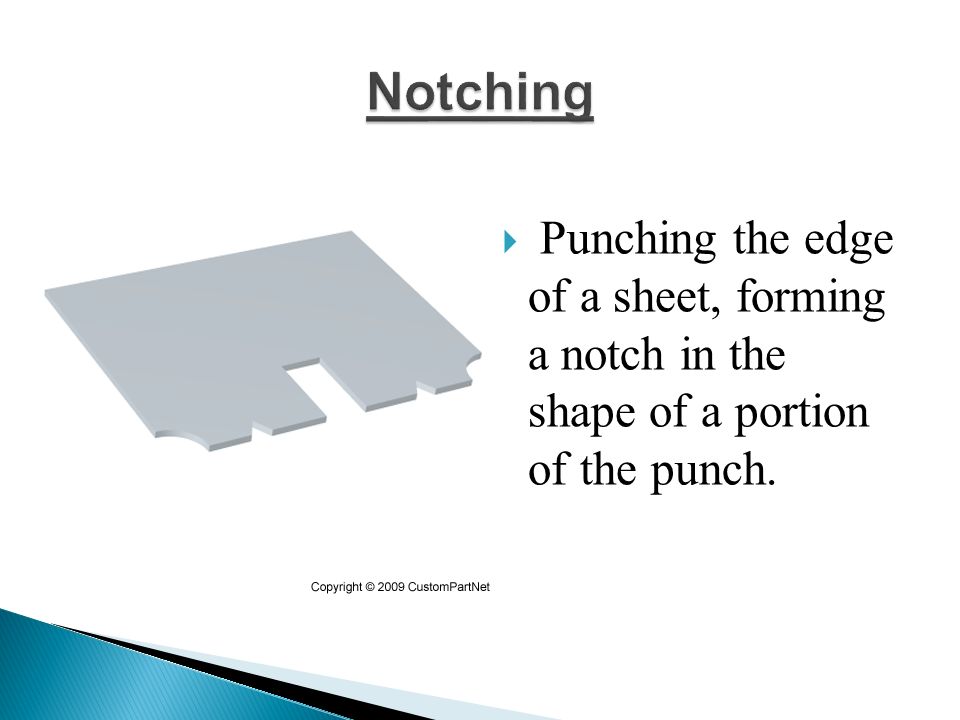

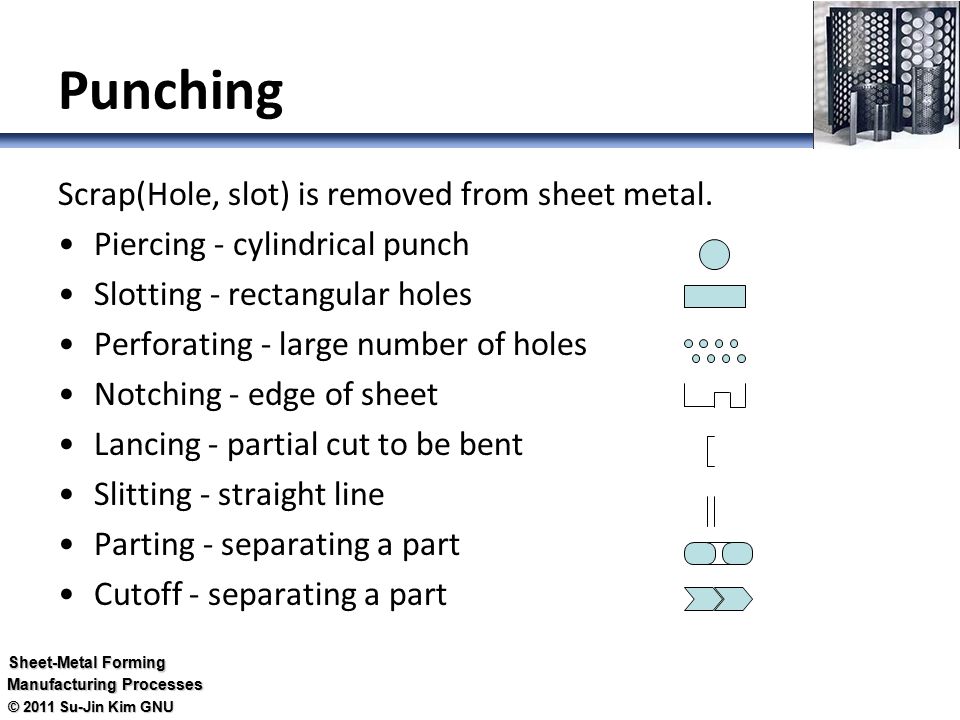

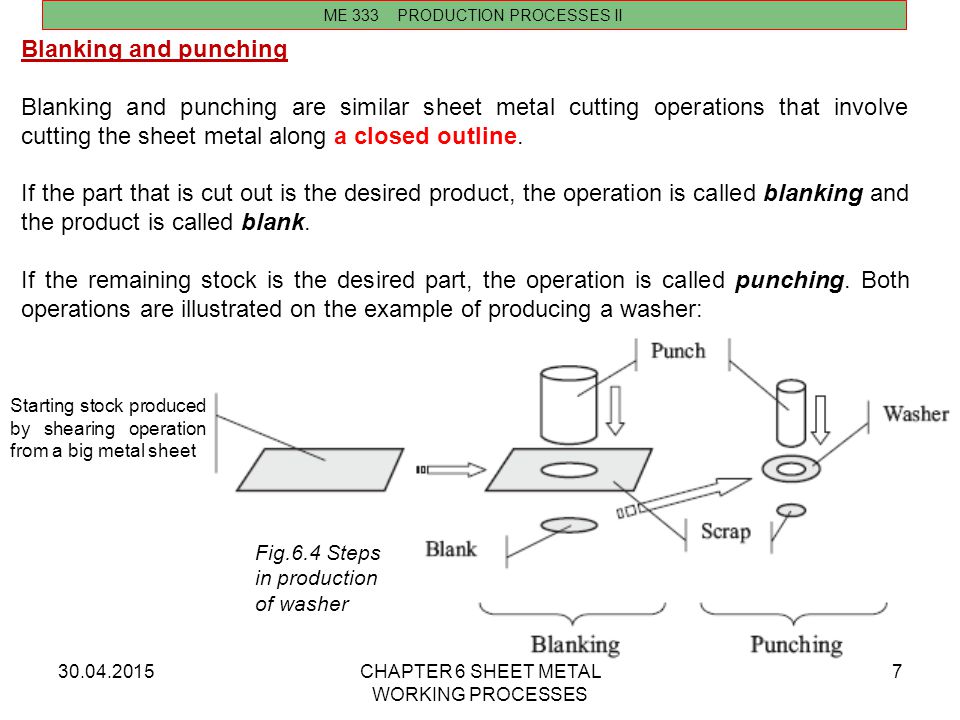

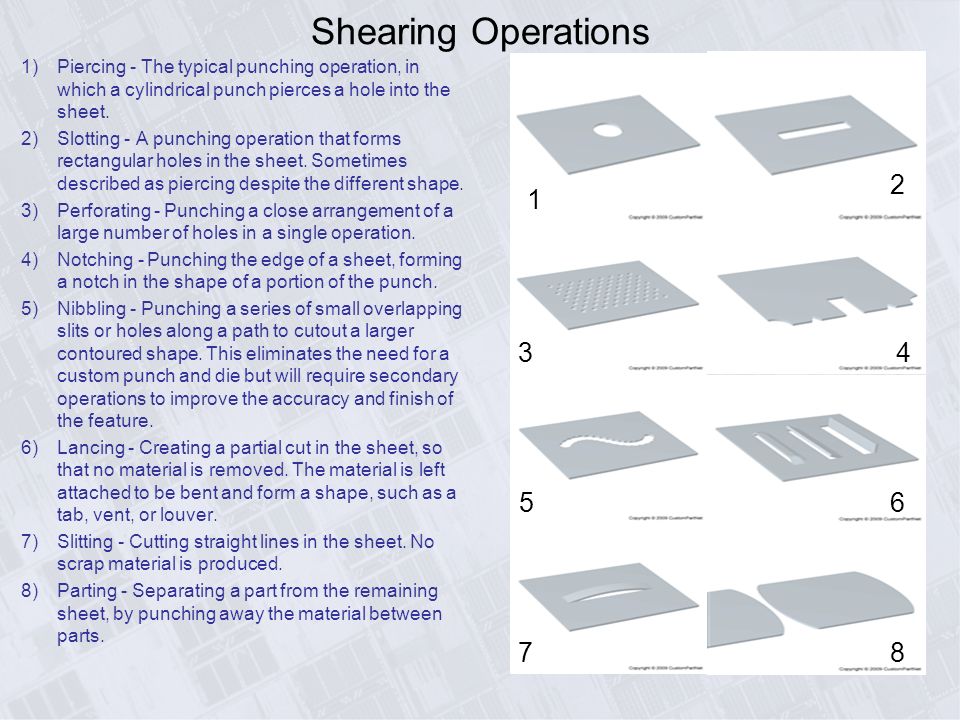

Piercing operation in sheet metal. Lancing is a partial cutting operation where bending and piercing is done using the same punch. It consists of several different material parting operations such a piercing perforating shearing notching cutoff and blanking. It has 3 basic stages. The process and machinery are usually the same as that used in blanking except that the piece being punched out is scrap in the piercing process.

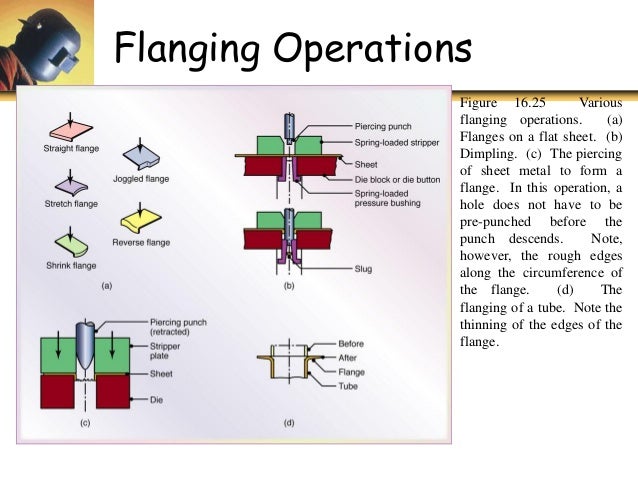

In other words piercing operation produces an extruded hole in sheet metal. Piercing lancing perforating notching nibbling trimming shaving. As a result of applied force from the piercing tool sheet metal starts tearing and produces extruded hole slot. Other piercing techniques lancing.

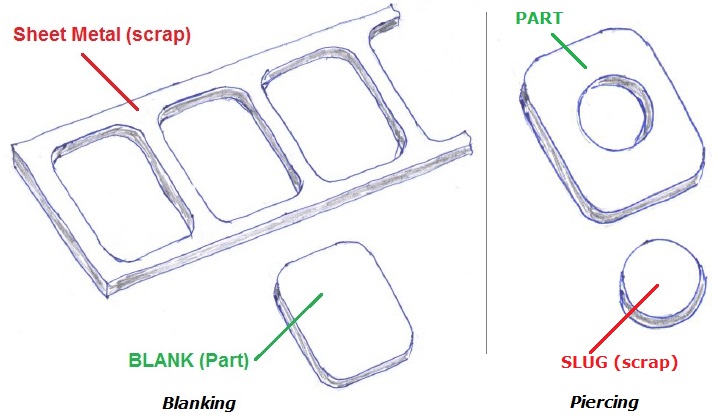

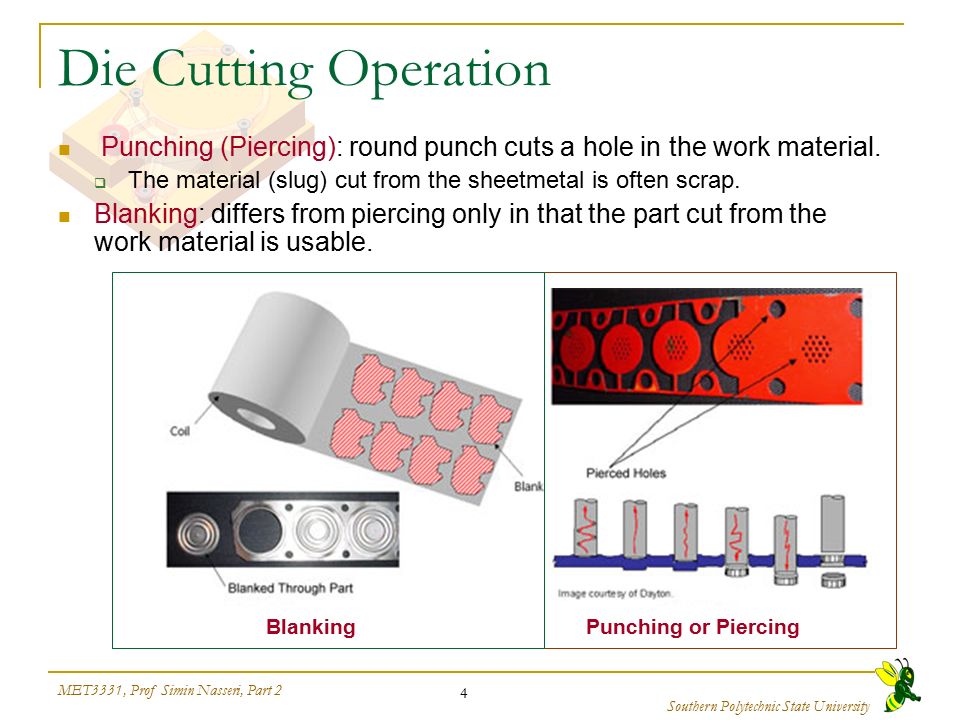

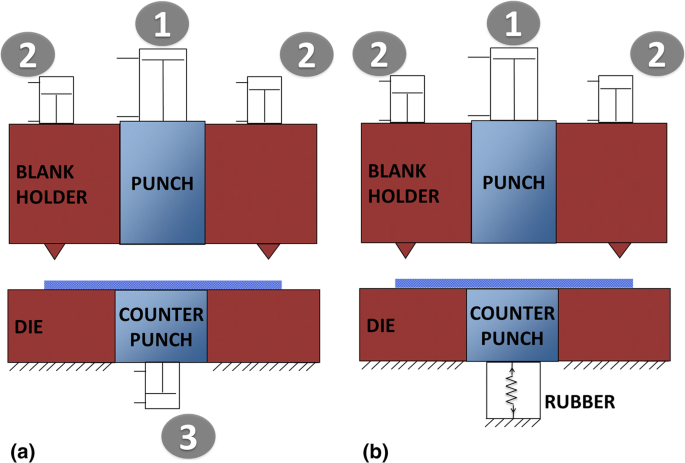

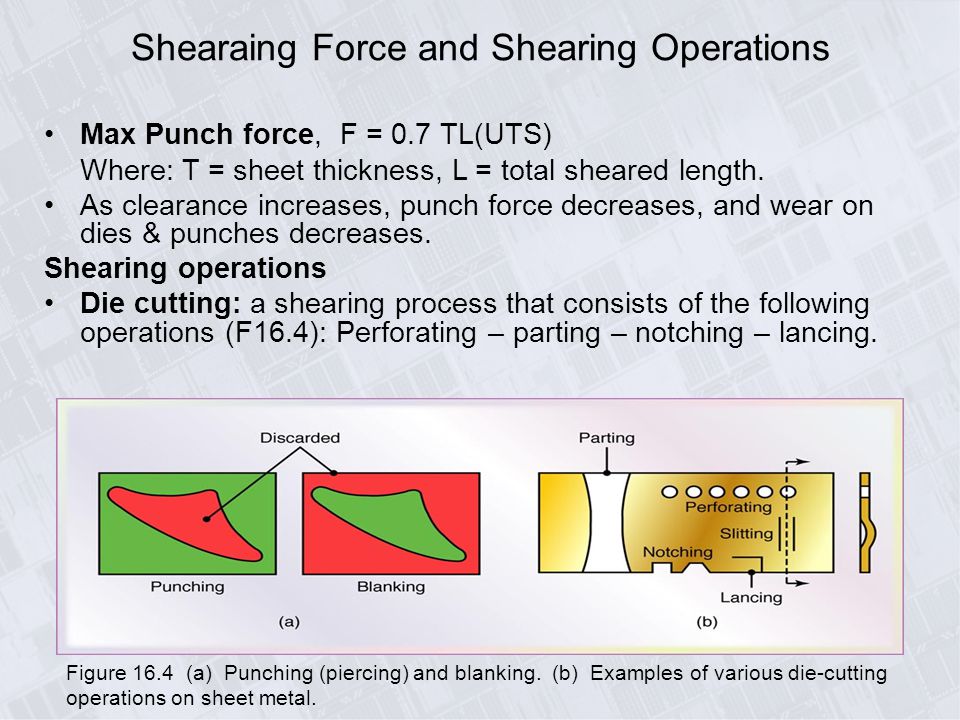

Piercing operation produces an extruded hole or slot. Piercing is a shearing process where a punch and die are used to create a hole in sheet metal or a plate. If the small removed piece is the useful part and the rest is scrap the operation is called blanking. In blanking the piece is cut off from the sheet and it becomes a finished part.

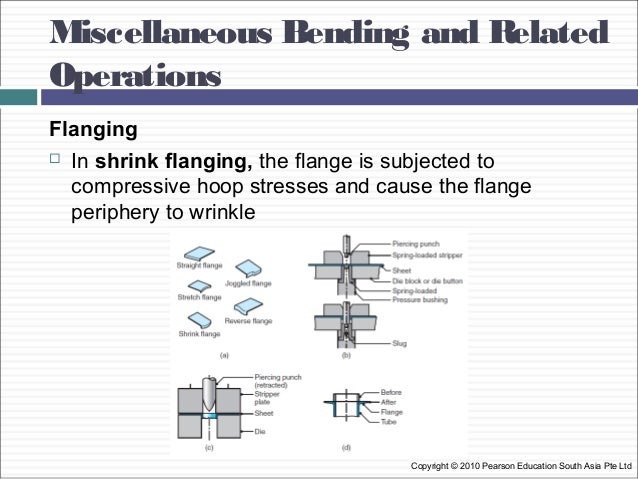

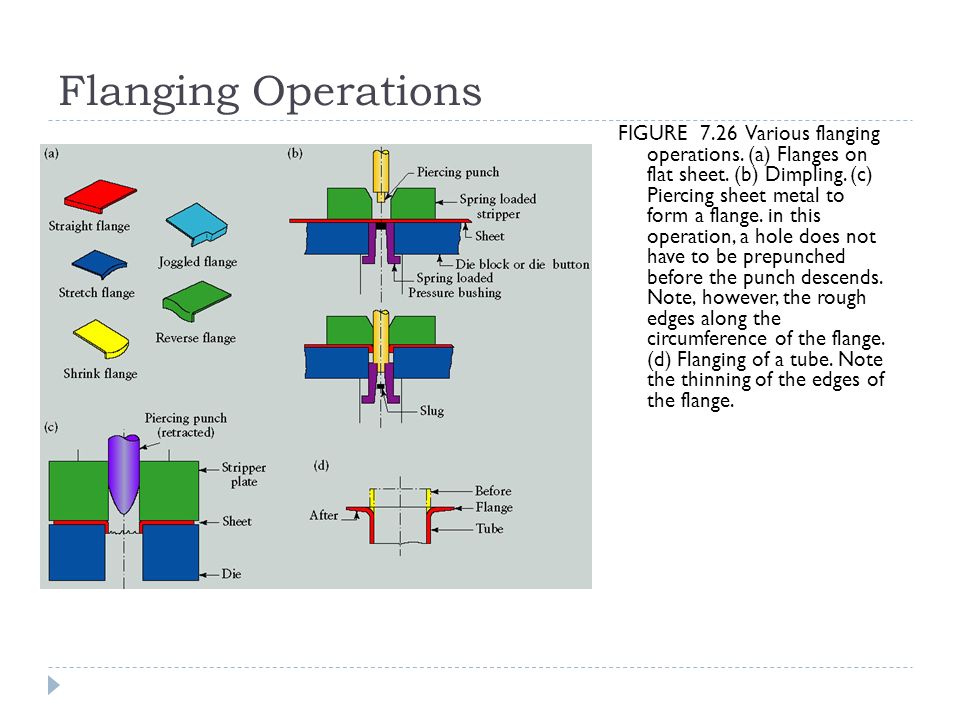

A key part of this process is that there is not reduction of material only a modification in its geometry. Shaving is a finishing operation where a small amount of material is removed from a previously pierced hole. Plastic deformation fracture shear. Lancing is a piercing operation in which the workpiece is sheared and bent with one strike of the die.

Punching or blanking is a process in which the punch removes a portion of material from the larger piece or a strip of sheet metal. This is a form of.