Phenolic Foam Roof Insulation Corrosion

The corrosion created the potential for equipment or people to fall through compromised areas.

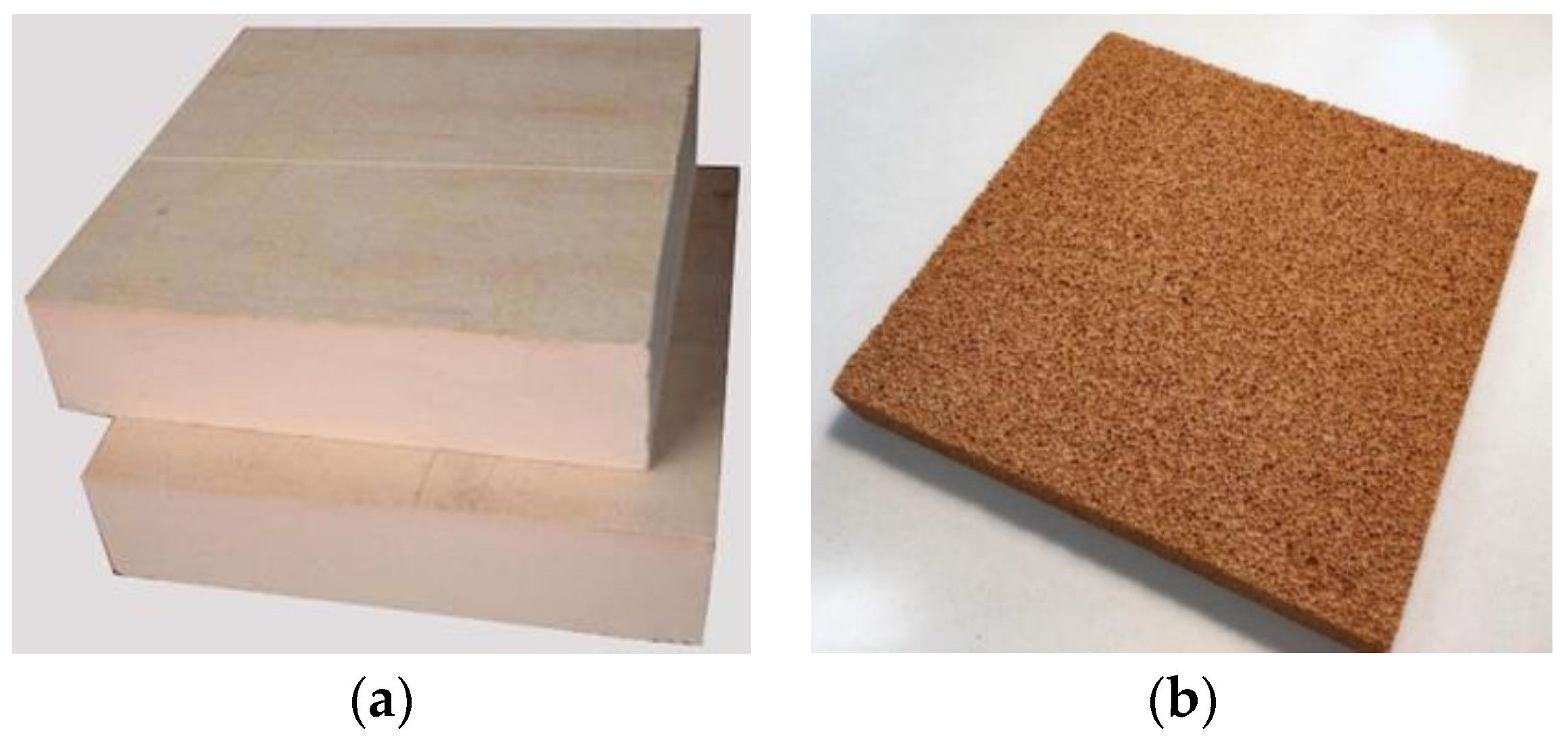

Phenolic foam roof insulation corrosion. The phenolic insulation also has a history of crumbling and easily crushes when walked on leaving a residue on the decking. While roof systems containing phenolic foam roof insulation may be in good shape it is important to repair and remediate decks as soon as possible. Once a property is identified as part of the class action lawsuit it becomes an issue should the. It offers many advantages including excellent density and an r value of 4 8 per inch of thickness which forms an effective barrier against heat transfer and thus helps you save energy around the house.

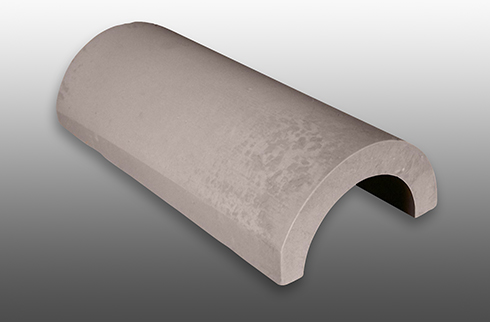

Phenolic foam insulation used to be available in board form but today is only sold as a type of foamed in place insulation. In order to have corrosion three things are required oxygen moisture and a catalyst. The rooftop of the test hut where 8 different types of phenolic foam rigid insulation underwent a corrosion test. These photos show the inside of the fraunhofer rooftop test hut and show how water is delivered to the roof system to load the installed phenolic foam rigid insulation with moisture.

Judging by the building s age and structure the engineers believed phenolic foam insulation was the source. The phenolic foam roof insulation turned out to have a critical flaw.

:max_bytes(150000):strip_icc()/__opt__aboutcom__coeus__resources__content_migration__treehugger__images__2013__08__spray-foam-closeup-111c31b987494e6a80c042183099bcb8.jpg)