Partial Bend Sheet Metal

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.

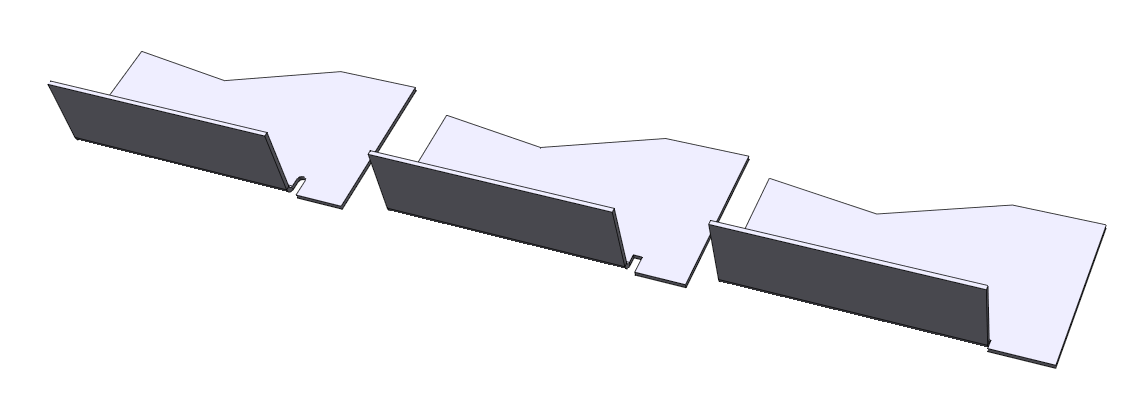

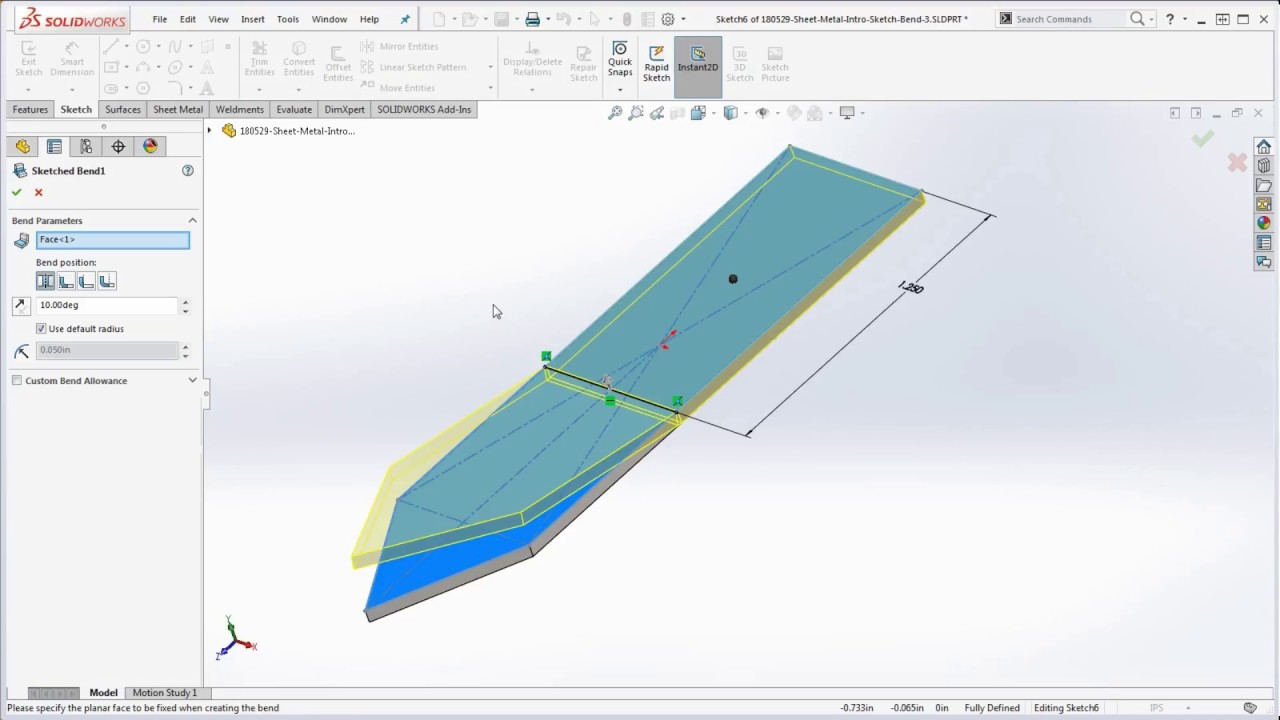

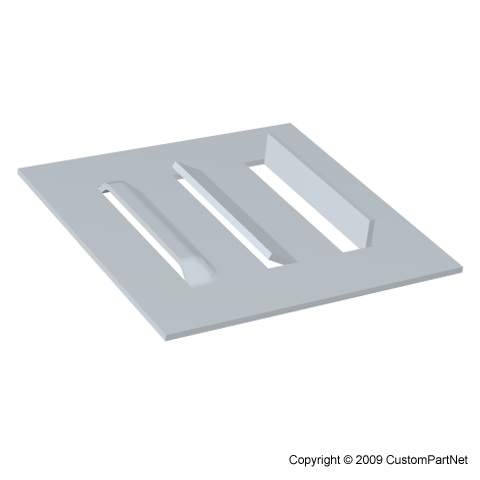

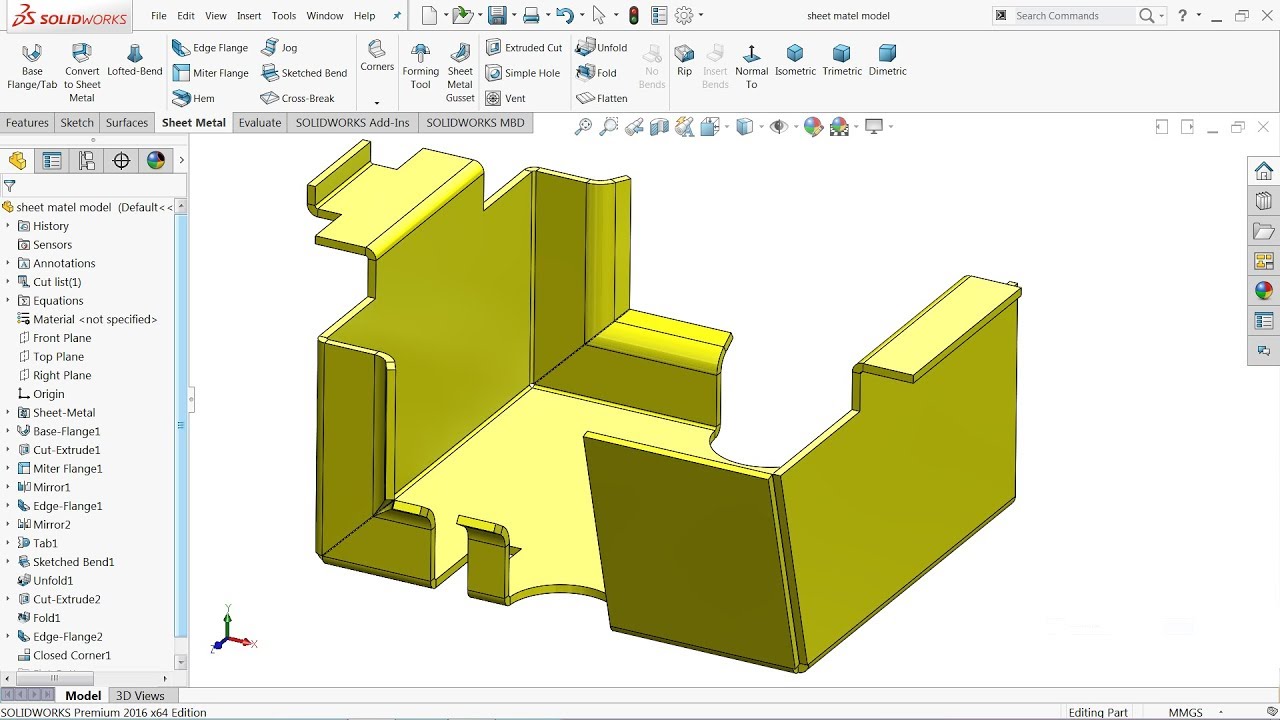

Partial bend sheet metal. A typical example is represented by the partial bend on a side with the bend line internal to the thickness. Synchronous sheet metal is pretty cool even cooler than just normal synchronous modeling if you ll excuse that word. Bending is one of the most common sheet metal fabrication operations. For example if you make a partial flange as above using all the defaults the software makes relief cuts at the end of the bends as shown to the right.

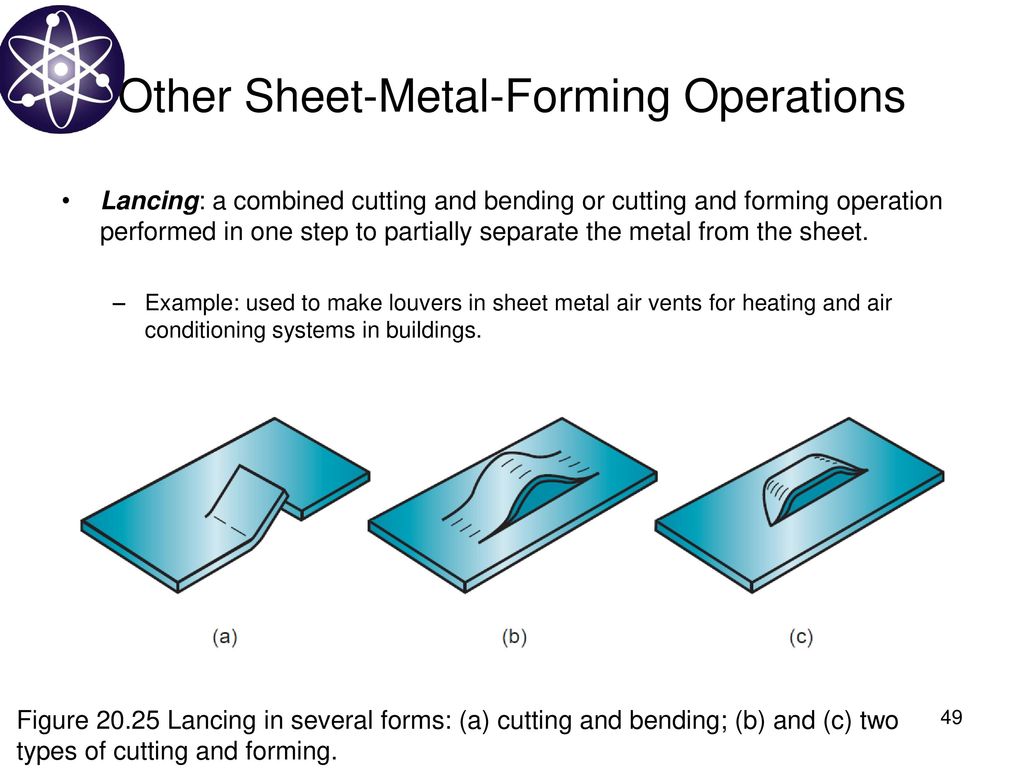

Sheet metal 4 2 bend taper sheet metal ribbon toolbar editing it is used to miter the flange to change its profile and avoid interfering with other flanges or make some gap especially on the imported sheet metal which has no flange features. In this tutorial we will learn about the basics of solid edge software s sheet metal functionality by creating a model named cover. Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape. The sheet metal functions of thinkdesign can perform automatically and under certain conditions different types of rips by using the correct parameters according to the feature to be executed on the flange.

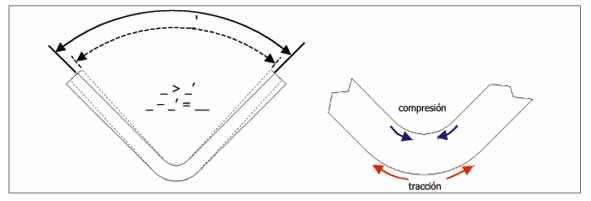

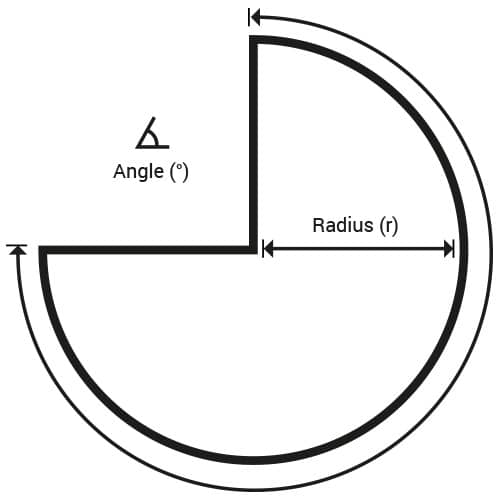

Similar to other metal forming processes bending changes the shape of the work piece while the volume of material will remain the same. Sheet metal bending is the plastic deformation of the work over an axis creating a change in the part s geometry. Step 01 open the file named sheetmetal functions z3 13 bend taper as follows. The force must exceed the material s yield strength to achieve a plastic deformation.

Partial folding name is due to the fact that the sheet during bending is in contact with 3 points a b and c of the lower picture of the equipment. With this method of bending it is possible to. This is done through the application of force on a workpiece. Springback is the partial recovery of the work from the bend to its geometry before the.